Project to Move Engineered Tissue and Organs from Lab to the Bedside, Operating Room

|

By LabMedica International staff writers Posted on 13 May 2014 |

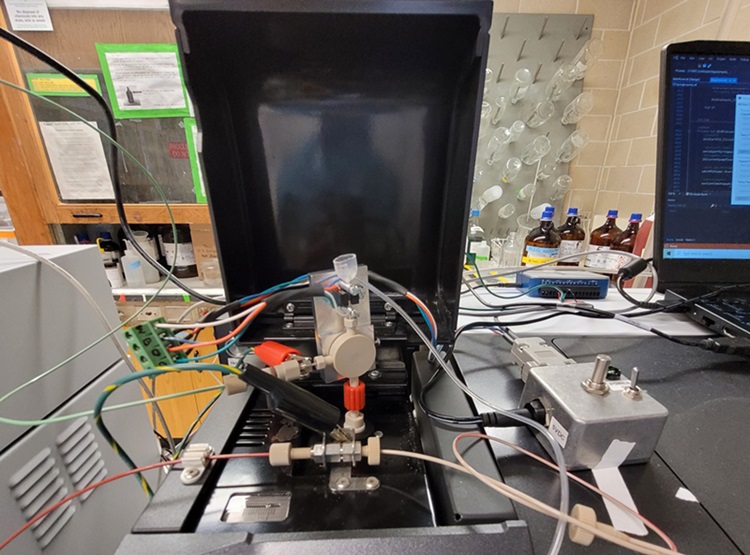

Image: Lab-grown vaginal organs implanted in patients (Photo courtesy of the Wake Forest Institute for Regenerative Medicine).

As developments in lab-created organs and tissues continue to advance, the challenge becomes how to translate the technology from the laboratory to the operating room. Two US universities are now exploring manufacturing platforms to mass produce customized engineered tissues and organs.

Developing a way to scale up personalized lab-created organs and tissues would benefit patients around the world who must wait for donated organs to receive transplants. North Carolina (NC) State University’s (Raleigh, NC, USA) industrial and systems engineering department (NC State ISE) engineers are partnering with biomedical scientists at the Wake Forest Institute for Regenerative Medicine (WFIRM; Winston-Salem, NC, USA). Together, the institutions are creating advancements in 3D technology, computer-aided modeling and intelligent automation to print tissues and organs for patients. With their focus on precision, computer modeling and three-dimensional (3D) printing will help scientists scale up the tissue engineering processes currently being done manually.

The future of organs-on-demand requires the mass generation of precise parts that are specific to each individual recipient. The development entails combining the cells and a scaffold, or a model that forms the essential shape. The support structure is designed to gradually dissolve after implantation in the body. At the same time, the scaffolding material is being absorbed by the body, and the cells lay down materials to form a permanent support structure, progressively replacing the engineered scaffold with a new organ.

Leading corporate and education specialists in medicine, engineering, and science gathered at this year’s Regenerative Medicine Foundation Conference, May 5-7, 2014, held in San Francisco, CA, USA, to share firsthand accounts of their visions and challenges of bio-tissue manufacturing. Dr. Binil Starly, director of NC State ISE’s laboratory for engineering biological tissue systems, uses bioprinting to devise ways for mass producing engineered tissue and also shared data about these latest developments, including a patent-pending process, which is collaboration between WFIRM and NCSU, for providing replacement skin for burn victims.

“It is one thing to be able to grow an organ but another to take that ability to the bedside, so involving manufacturing engineers early on in the biological research phase is vital to achieving commercialization,” said Dr. Starly. “NC State ISE reviews the scientific process for growing tissue cells, and then applies 3D technologies and algorithms to automate it, so a very sensitive biological process can be replicated safely and effectively.”

Dr. Anthony Atala, director of WFIRM and NC State ISE advisory board member, moderated a panel on the marketing of regenerative medicine therapies at the conference. WFIRM scientists have developed lab-grown organs, such as bladders, vaginal organs, and urine tubes successfully used in patients.

Related Links:

North Carolina State University

Wake Forest Institute for Regenerative Medicine

Developing a way to scale up personalized lab-created organs and tissues would benefit patients around the world who must wait for donated organs to receive transplants. North Carolina (NC) State University’s (Raleigh, NC, USA) industrial and systems engineering department (NC State ISE) engineers are partnering with biomedical scientists at the Wake Forest Institute for Regenerative Medicine (WFIRM; Winston-Salem, NC, USA). Together, the institutions are creating advancements in 3D technology, computer-aided modeling and intelligent automation to print tissues and organs for patients. With their focus on precision, computer modeling and three-dimensional (3D) printing will help scientists scale up the tissue engineering processes currently being done manually.

The future of organs-on-demand requires the mass generation of precise parts that are specific to each individual recipient. The development entails combining the cells and a scaffold, or a model that forms the essential shape. The support structure is designed to gradually dissolve after implantation in the body. At the same time, the scaffolding material is being absorbed by the body, and the cells lay down materials to form a permanent support structure, progressively replacing the engineered scaffold with a new organ.

Leading corporate and education specialists in medicine, engineering, and science gathered at this year’s Regenerative Medicine Foundation Conference, May 5-7, 2014, held in San Francisco, CA, USA, to share firsthand accounts of their visions and challenges of bio-tissue manufacturing. Dr. Binil Starly, director of NC State ISE’s laboratory for engineering biological tissue systems, uses bioprinting to devise ways for mass producing engineered tissue and also shared data about these latest developments, including a patent-pending process, which is collaboration between WFIRM and NCSU, for providing replacement skin for burn victims.

“It is one thing to be able to grow an organ but another to take that ability to the bedside, so involving manufacturing engineers early on in the biological research phase is vital to achieving commercialization,” said Dr. Starly. “NC State ISE reviews the scientific process for growing tissue cells, and then applies 3D technologies and algorithms to automate it, so a very sensitive biological process can be replicated safely and effectively.”

Dr. Anthony Atala, director of WFIRM and NC State ISE advisory board member, moderated a panel on the marketing of regenerative medicine therapies at the conference. WFIRM scientists have developed lab-grown organs, such as bladders, vaginal organs, and urine tubes successfully used in patients.

Related Links:

North Carolina State University

Wake Forest Institute for Regenerative Medicine

Latest BioResearch News

- Genome Analysis Predicts Likelihood of Neurodisability in Oxygen-Deprived Newborns

- Gene Panel Predicts Disease Progession for Patients with B-cell Lymphoma

- New Method Simplifies Preparation of Tumor Genomic DNA Libraries

- New Tool Developed for Diagnosis of Chronic HBV Infection

- Panel of Genetic Loci Accurately Predicts Risk of Developing Gout

- Disrupted TGFB Signaling Linked to Increased Cancer-Related Bacteria

- Gene Fusion Protein Proposed as Prostate Cancer Biomarker

- NIV Test to Diagnose and Monitor Vascular Complications in Diabetes

- Semen Exosome MicroRNA Proves Biomarker for Prostate Cancer

- Genetic Loci Link Plasma Lipid Levels to CVD Risk

- Newly Identified Gene Network Aids in Early Diagnosis of Autism Spectrum Disorder

- Link Confirmed between Living in Poverty and Developing Diseases

- Genomic Study Identifies Kidney Disease Loci in Type I Diabetes Patients

- Liquid Biopsy More Effective for Analyzing Tumor Drug Resistance Mutations

- New Liquid Biopsy Assay Reveals Host-Pathogen Interactions

- Method Developed for Enriching Trophoblast Population in Samples

Channels

Clinical Chemistry

view channel

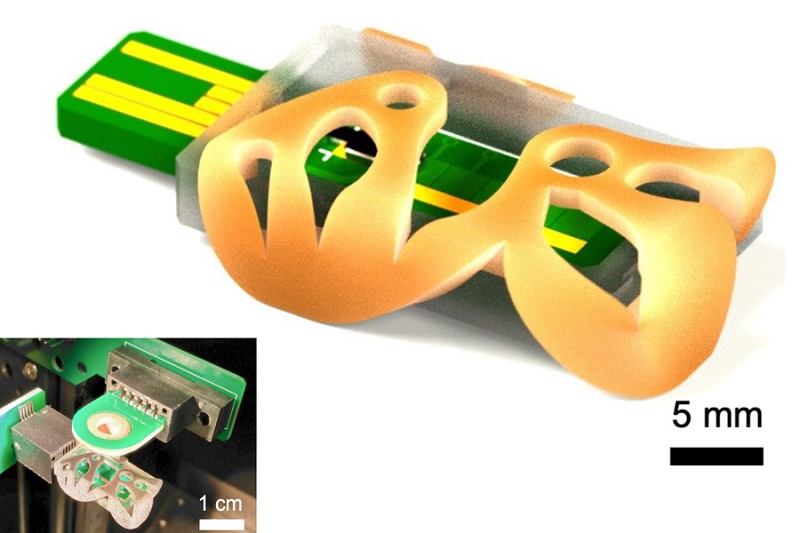

3D Printed Point-Of-Care Mass Spectrometer Outperforms State-Of-The-Art Models

Mass spectrometry is a precise technique for identifying the chemical components of a sample and has significant potential for monitoring chronic illness health states, such as measuring hormone levels... Read more.jpg)

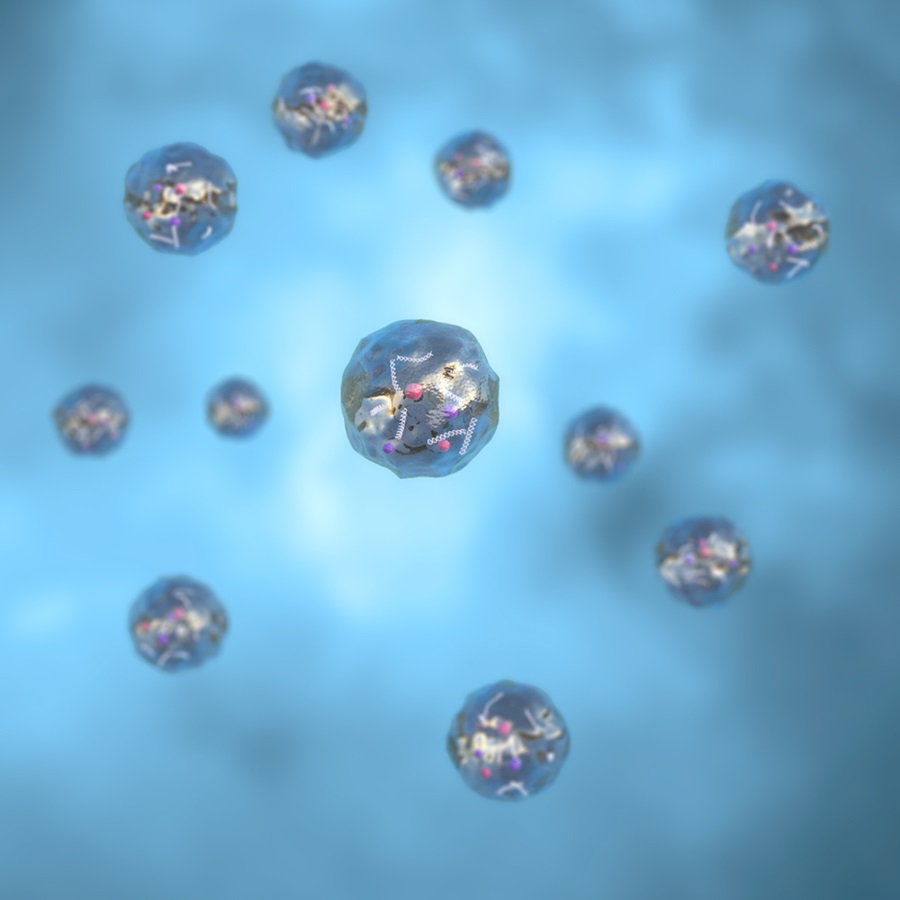

POC Biomedical Test Spins Water Droplet Using Sound Waves for Cancer Detection

Exosomes, tiny cellular bioparticles carrying a specific set of proteins, lipids, and genetic materials, play a crucial role in cell communication and hold promise for non-invasive diagnostics.... Read more

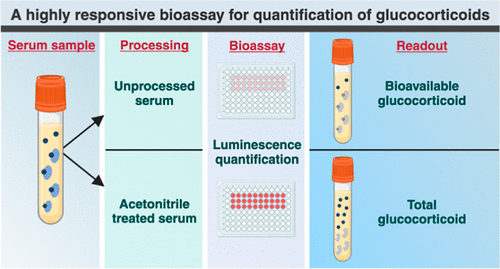

Highly Reliable Cell-Based Assay Enables Accurate Diagnosis of Endocrine Diseases

The conventional methods for measuring free cortisol, the body's stress hormone, from blood or saliva are quite demanding and require sample processing. The most common method, therefore, involves collecting... Read moreMolecular Diagnostics

view channelBlood Proteins Could Warn of Cancer Seven Years before Diagnosis

Two studies have identified proteins in the blood that could potentially alert individuals to the presence of cancer more than seven years before the disease is clinically diagnosed. Researchers found... Read moreUltrasound-Aided Blood Testing Detects Cancer Biomarkers from Cells

Ultrasound imaging serves as a noninvasive method to locate and monitor cancerous tumors effectively. However, crucial details about the cancer, such as the specific types of cells and genetic mutations... Read moreHematology

view channel

Next Generation Instrument Screens for Hemoglobin Disorders in Newborns

Hemoglobinopathies, the most widespread inherited conditions globally, affect about 7% of the population as carriers, with 2.7% of newborns being born with these conditions. The spectrum of clinical manifestations... Read more

First 4-in-1 Nucleic Acid Test for Arbovirus Screening to Reduce Risk of Transfusion-Transmitted Infections

Arboviruses represent an emerging global health threat, exacerbated by climate change and increased international travel that is facilitating their spread across new regions. Chikungunya, dengue, West... Read more

POC Finger-Prick Blood Test Determines Risk of Neutropenic Sepsis in Patients Undergoing Chemotherapy

Neutropenia, a decrease in neutrophils (a type of white blood cell crucial for fighting infections), is a frequent side effect of certain cancer treatments. This condition elevates the risk of infections,... Read more

First Affordable and Rapid Test for Beta Thalassemia Demonstrates 99% Diagnostic Accuracy

Hemoglobin disorders rank as some of the most prevalent monogenic diseases globally. Among various hemoglobin disorders, beta thalassemia, a hereditary blood disorder, affects about 1.5% of the world's... Read moreImmunology

view channel.jpg)

AI Predicts Tumor-Killing Cells with High Accuracy

Cellular immunotherapy involves extracting immune cells from a patient's tumor, potentially enhancing their cancer-fighting capabilities through engineering, and then expanding and reintroducing them into the body.... Read more

Diagnostic Blood Test for Cellular Rejection after Organ Transplant Could Replace Surgical Biopsies

Transplanted organs constantly face the risk of being rejected by the recipient's immune system which differentiates self from non-self using T cells and B cells. T cells are commonly associated with acute... Read more

AI Tool Precisely Matches Cancer Drugs to Patients Using Information from Each Tumor Cell

Current strategies for matching cancer patients with specific treatments often depend on bulk sequencing of tumor DNA and RNA, which provides an average profile from all cells within a tumor sample.... Read more

Genetic Testing Combined With Personalized Drug Screening On Tumor Samples to Revolutionize Cancer Treatment

Cancer treatment typically adheres to a standard of care—established, statistically validated regimens that are effective for the majority of patients. However, the disease’s inherent variability means... Read moreMicrobiology

view channel

Integrated Solution Ushers New Era of Automated Tuberculosis Testing

Tuberculosis (TB) is responsible for 1.3 million deaths every year, positioning it as one of the top killers globally due to a single infectious agent. In 2022, around 10.6 million people were diagnosed... Read more

Automated Sepsis Test System Enables Rapid Diagnosis for Patients with Severe Bloodstream Infections

Sepsis affects up to 50 million people globally each year, with bacteraemia, formerly known as blood poisoning, being a major cause. In the United States alone, approximately two million individuals are... Read moreEnhanced Rapid Syndromic Molecular Diagnostic Solution Detects Broad Range of Infectious Diseases

GenMark Diagnostics (Carlsbad, CA, USA), a member of the Roche Group (Basel, Switzerland), has rebranded its ePlex® system as the cobas eplex system. This rebranding under the globally renowned cobas name... Read more

Clinical Decision Support Software a Game-Changer in Antimicrobial Resistance Battle

Antimicrobial resistance (AMR) is a serious global public health concern that claims millions of lives every year. It primarily results from the inappropriate and excessive use of antibiotics, which reduces... Read morePathology

view channel

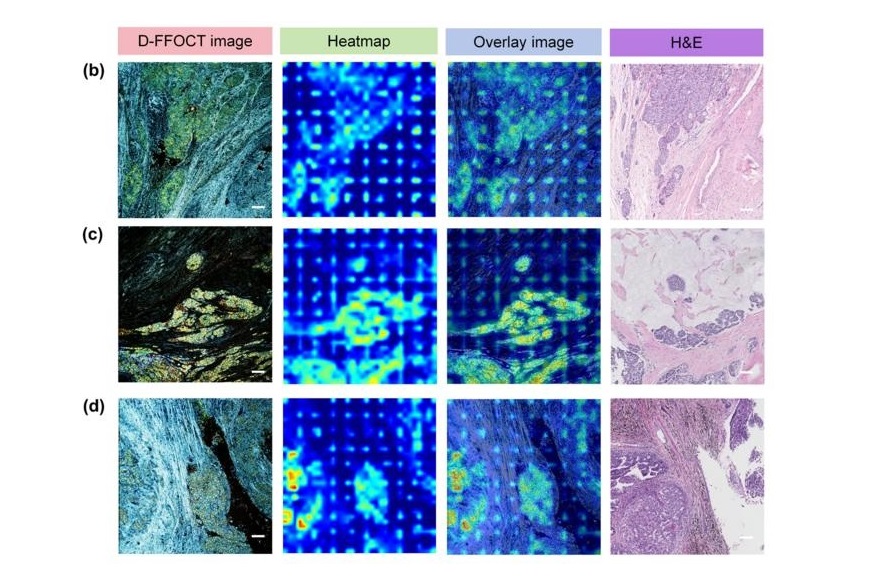

AI Integrated With Optical Imaging Technology Enables Rapid Intraoperative Diagnosis

Rapid and accurate intraoperative diagnosis is essential for tumor surgery as it guides surgical decisions with precision. Traditional intraoperative assessments, such as frozen sections based on H&E... Read more

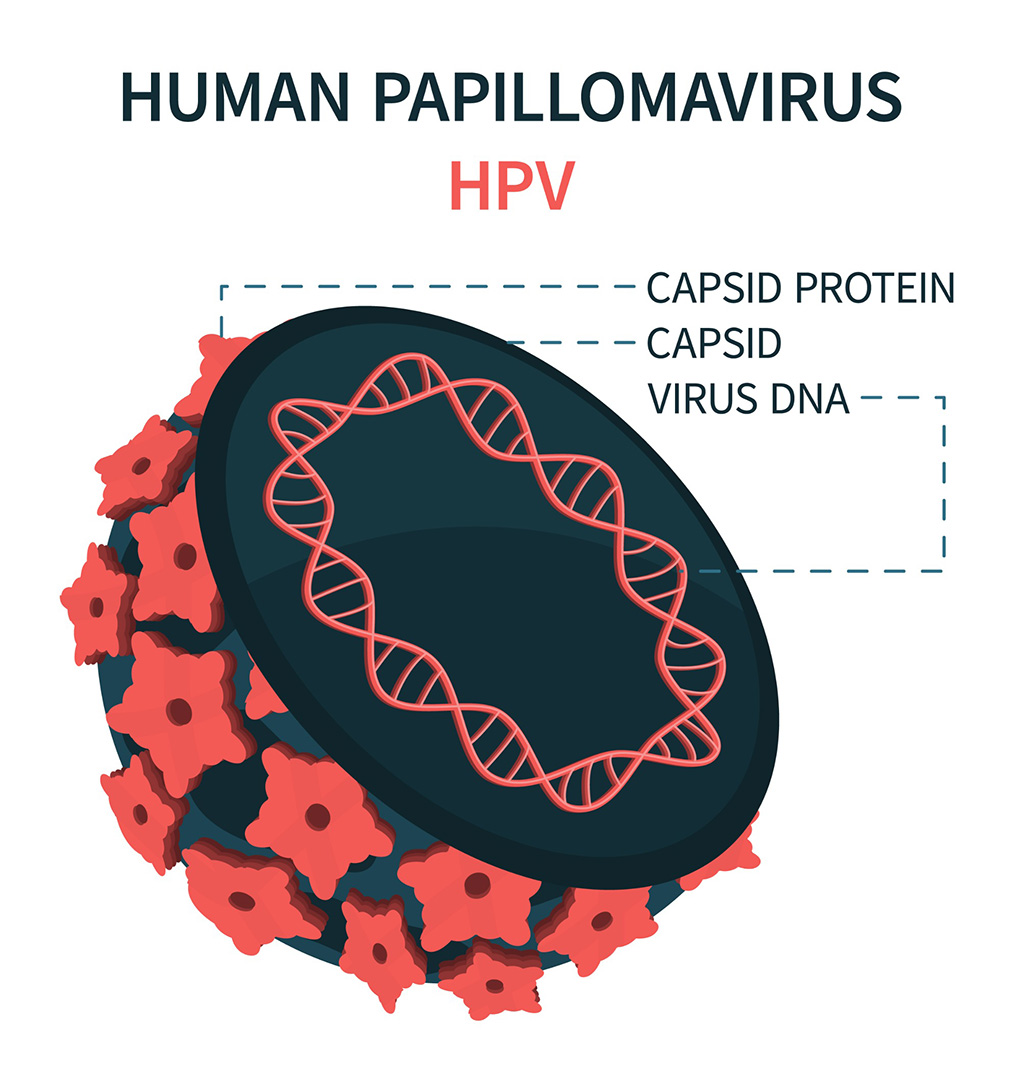

HPV Self-Collection Solution Improves Access to Cervical Cancer Testing

Annually, over 604,000 women across the world are diagnosed with cervical cancer, and about 342,000 die from this disease, which is preventable and primarily caused by the Human Papillomavirus (HPV).... Read moreHyperspectral Dark-Field Microscopy Enables Rapid and Accurate Identification of Cancerous Tissues

Breast cancer remains a major cause of cancer-related mortality among women. Breast-conserving surgery (BCS), also known as lumpectomy, is the removal of the cancerous lump and a small margin of surrounding tissue.... Read moreTechnology

view channel

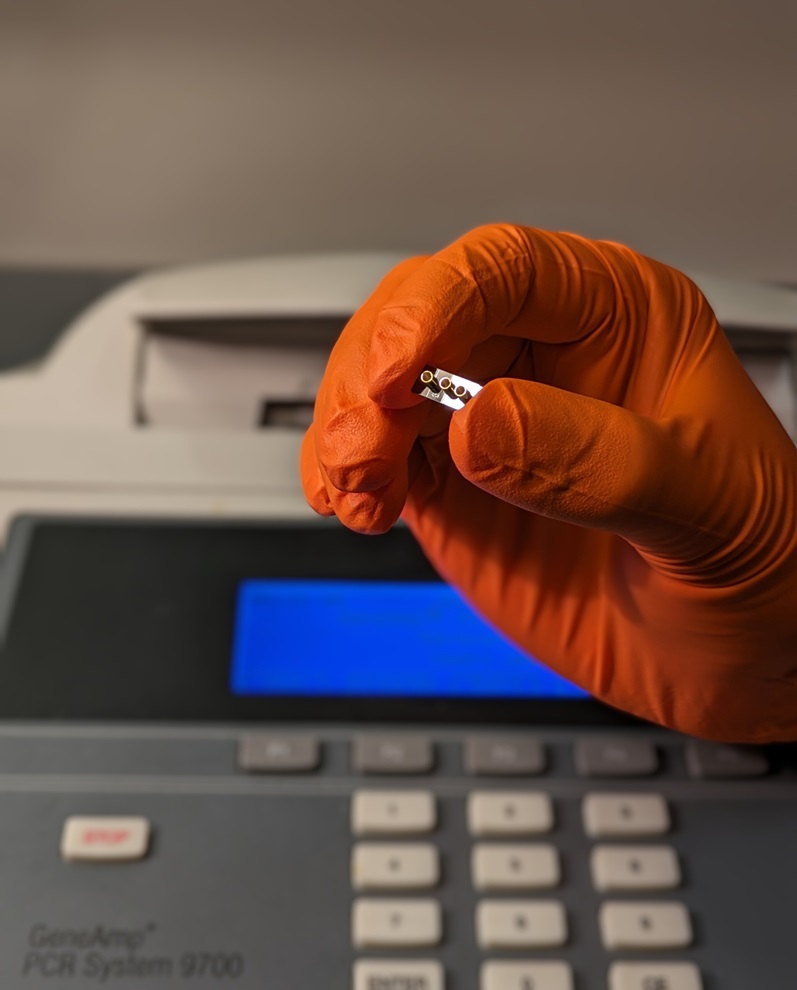

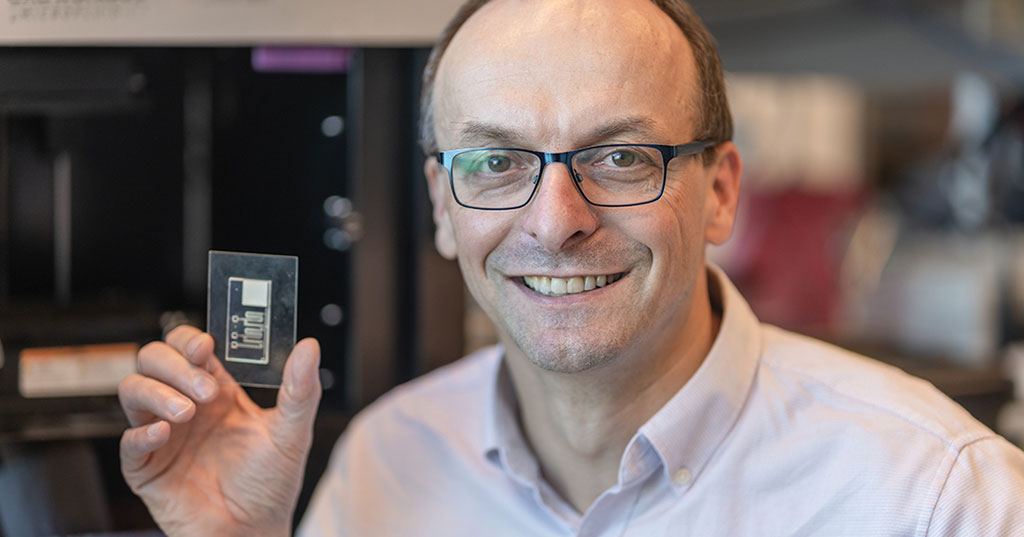

New Diagnostic System Achieves PCR Testing Accuracy

While PCR tests are the gold standard of accuracy for virology testing, they come with limitations such as complexity, the need for skilled lab operators, and longer result times. They also require complex... Read more

DNA Biosensor Enables Early Diagnosis of Cervical Cancer

Molybdenum disulfide (MoS2), recognized for its potential to form two-dimensional nanosheets like graphene, is a material that's increasingly catching the eye of the scientific community.... Read more

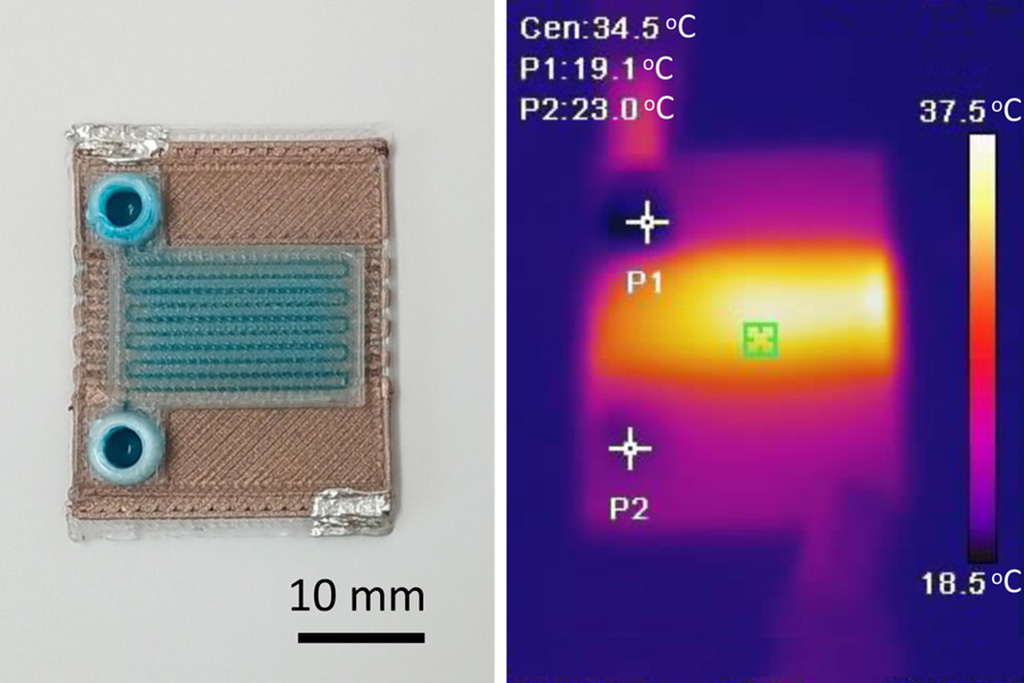

Self-Heating Microfluidic Devices Can Detect Diseases in Tiny Blood or Fluid Samples

Microfluidics, which are miniature devices that control the flow of liquids and facilitate chemical reactions, play a key role in disease detection from small samples of blood or other fluids.... Read more

Breakthrough in Diagnostic Technology Could Make On-The-Spot Testing Widely Accessible

Home testing gained significant importance during the COVID-19 pandemic, yet the availability of rapid tests is limited, and most of them can only drive one liquid across the strip, leading to continued... Read moreIndustry

view channel

Danaher and Johns Hopkins University Collaborate to Improve Neurological Diagnosis

Unlike severe traumatic brain injury (TBI), mild TBI often does not show clear correlations with abnormalities detected through head computed tomography (CT) scans. Consequently, there is a pressing need... Read more

Beckman Coulter and MeMed Expand Host Immune Response Diagnostics Partnership

Beckman Coulter Diagnostics (Brea, CA, USA) and MeMed BV (Haifa, Israel) have expanded their host immune response diagnostics partnership. Beckman Coulter is now an authorized distributor of the MeMed... Read more_1.jpg)

_1.jpg)

.jpg)