Continuous Purification Technique Should Significantly Reduce Antibody Production Costs

By LabMedica International staff writers

Posted on 30 Mar 2015

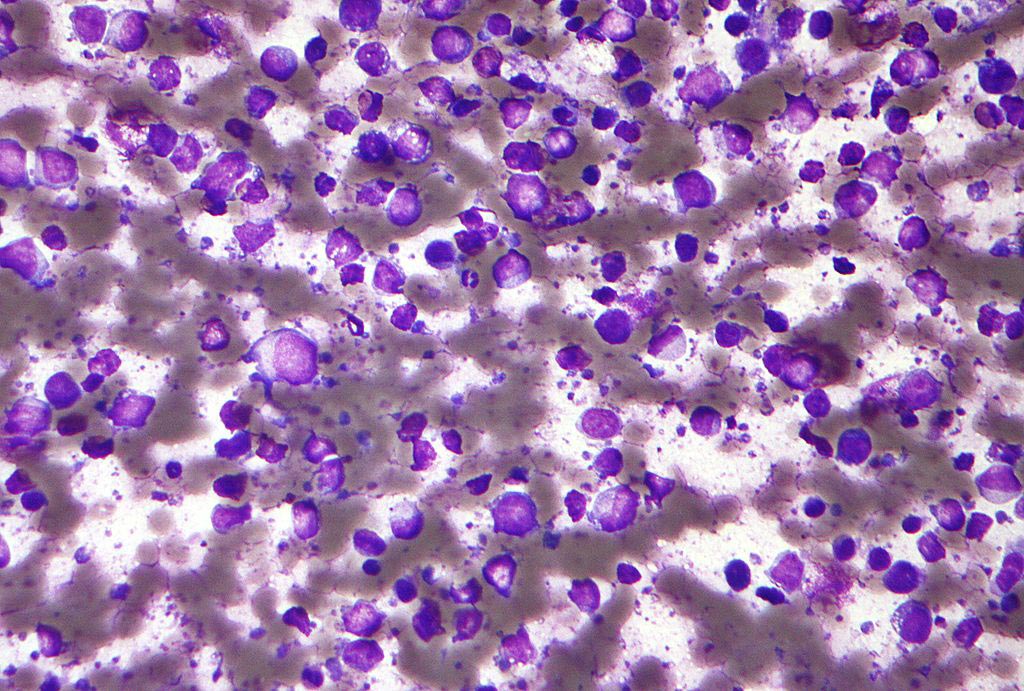

An Austrian biotechnology firm has developed a method for the continuous purification of recombinant antibodies from cultures of clarified Chinese hamster ovary (CHO) cells that promises to significantly reduce the production costs of these important therapeutic and research materials.Posted on 30 Mar 2015

Investigators at the Austrian Center of Industrial Biotechnology (Graz) replaced batch manufacture of protein A affinity chromatography-purified antibodies with a much simpler and cheaper continuous precipitation method. Currently about 80% of antibody production costs are due to the purification step.

Image: An Austrian Research Center of Industrial Biotechnology researcher is shown working with a laboratory scale continuous antibody purification reactor (Photo courtesy of the Austrian Research Center of Industrial Biotechnology).

The new precipitation process is based on a cheap mineral salt (CaCl2) and an organic solvent (ethanol). In this system purification of the antibodies depends on calcium-phosphate flocculation with subsequent cold ethanol precipitation in a tubular reactor that is a double-pipe heat exchanger operated in counter-current flow mode.

In a feasibility study that was published in the March 17, 2015, online edition of the Biotechnology Journal the investigators showed that the time from startup until attaining steady state conditions was reached in less than 15 minutes, and both reactors were operated for several hours at steady state without manual intervention, delivering antibody at a constant yield and purity. An overall yield of greater than 90%, with a host cell protein reduction from 42,777 to 9,000 parts per million and a DNA reduction from 359 to 7 parts per million, could be achieved for the antibody investigated. This system enabled cell culture supernatants with low or high antibody titer to be processed with constant reactor size and without changing any parameters or increasing precipitant consumption. Aggregate levels were below 1% under all conditions tested.

"Our method shows great potential as a new platform technology for the pharmaceutical industry," said senior author Dr. Alois Jungbauer, professor of biotechnology and head of bioprocess engineering at the Austrian Centre of Industrial Biotechnology.

Related Links:

Austrian Center of Industrial Biotechnology