Optoelectrokinetic Tech Underlies New Biochip Approach

By LabMedica International staff writers

Posted on 05 Feb 2013

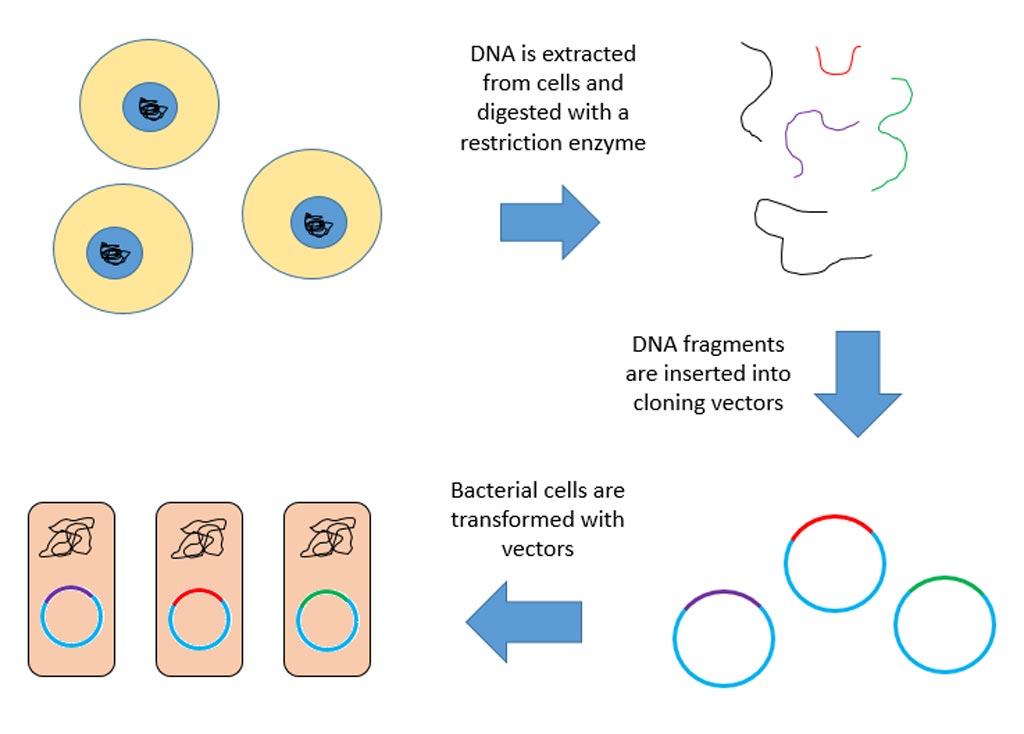

A recently developed optoelectrokinetic manipulation technique was used to separate microorganisms according to size, which demonstrated the potential of this method for the development of "lab-on-a-chip" diagnostic technologies.Posted on 05 Feb 2013

The technique, rapid electrokinetic patterning - or REP, works by focusing an infrared laser to heat a fluid in a microchannel containing particles or bacteria. An electric field is applied that combined with the laser's heating action causes the fluid to circulate in a "microfluidic vortex" that functions like a centrifuge to isolate particles based on size.

A detailed description of the method, which was used to collect three different types of microorganisms: the bacterium Shewanella oneidensis MR-1; the single-cell spherical fungus Saccharomyces cerevisiae; and the spherical bacterium Staphylococcus aureus, was published in the December 7, 2012, issue of the journal Lab on a Chip.

Senior author Dr. Steven T. Wereley, professor of mechanical engineering at Purdue University (West Lafayette, IN, USA), said, "By properly choosing the electrical frequency we can separate blood components, such as platelets. Say you want to collect Shewanella bacteria, so you use a certain electrical frequency and collect them. Then the next day you want to collect platelets from blood. That is going to be a different frequency. We foresee the ability to dynamically select what you will collect, which you could not do with conventional tools. The new results demonstrate that REP can be used to sort biological particles but also that the technique is a powerful tool for development of a high-performance on-chip bioassay system."

"It will not be on the market in a year," said Dr. Wereley. "We are still in the research end of this. We are sort of at the stage of looking for the killer app for this technology."

The REP method may also have applications in the field of nanomanufacturing due to its ability to assemble suspensions of particles known as colloids. This may be particularly relevant to the pharmaceutical industry, as a number of drugs are manufactured from solid particles suspended in liquid. Currently particles are collected and separated from the liquid by a process of filtration and centrifugation—methods not now available for production use at the nano level.

Related Links:

Purdue University