Engineers Design First Long-Lived Nanoscale Bubbles

By Biotechdaily staff writers

Posted on 25 Jun 2008

With the aid of kitchen mixers, engineers have constructed for the first time permanent nanoscale bubbles--bubbles that last for more than a year--from batches of foam made from a mixture of glucose syrup, sucrose stearate, and water. Posted on 25 Jun 2008

The research, published in the May 30, 2008, issue of the journal Science, was led by Dr. Howard A. Stone, from the Harvard University School of Engineering and Applied Sciences (SEAS; Cambridge, MA, USA), and had its beginnings in a conference talk on foams delivered in 2005 by Dr. Rodney Bee, a retired Unilever (London, UK) physical chemist. Dr. Bee, who had been researching ice cream for the food, beverage, and personal-care products company, was interested in finding ways to extend the life of foams and other gas-infused mixtures like ice cream. He had produced an unusual bubble formation in the course of his research, and he included a photograph of it in the presentation.

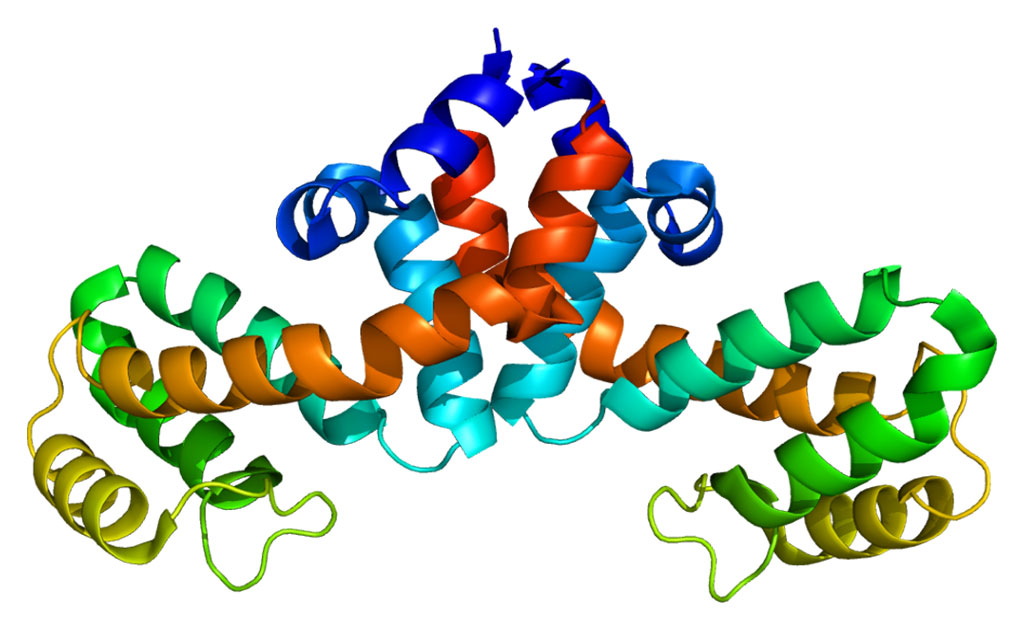

Dr. Stone, a Harvard professor of engineering and applied mathematics, and associate dean for applied physical sciences and engineering, was in the audience when Dr. Bee projected an image of a micrometer-size bubble with a distinctive polygonal geometry. The bubble surface appeared to be faceted with regular pentagonal, hexagonal, and heptagonal domains that intersected to form a soccer ball-like structure. None of the faces spanned more than 50 nm. "Small bubbles on that scale never last because of surface tension--they instantly disappear. What Rodney showed on that screen was extraordinary,” stated Dr. Stone. "It was impossible; we all thought it was impossible.”

Smaller bubbles have a greater surface tension and a higher gas pressure than larger ones. As a result, larger bubbles usually grow at the expense of smaller ones, which have very short lifetimes. "I asked him how he created his foams, and he said he used an ordinary kitchen mixer. The next day I went out and bought a kitchen mixer for the lab,” explained Dr. Stone.

The research study, conducted by SEAS graduate student Emilie Dressaire in collaboration with Unilever colleagues, revealed that when the bubbles were covered with the chosen surfactant mixture, the surfactant molecules crystallized to form nearly impermeable shells over the bubble surfaces. The resulting shells possessed an elasticity that allowed them to buckle over time into a remarkably regular and stable pattern. Measurements of the micro bubbles' stability extended over more than a year, and the structural integrity of the bubbles held for the entire period.

The investigators noted that future applications of these microbubbles could significantly extend the lifetimes of common gas-liquid products that experience rapid disintegration, such as aerated personal-care products and contrast agents for ultrasound imaging.

The research was funded by Unilever.

Related Links:

Harvard University School of Engineering and Applied Sciences