New Technology for Making Nanoparticles

By Biotechdaily staff writers

Posted on 11 Jul 2005

A new technology breakthrough can create the world's tiniest manufactured particles for delivering drugs and biologic materials into the human body.Posted on 11 Jul 2005

The technology provides control over shape, size, and composition of material when manufacturing nanoparticles. This innovative new process has widespread applications, including drug formulation, drug delivery, medical imaging and disease detection, and nonmedical applications such as sensors, ink-jet printing, and microelectronics.

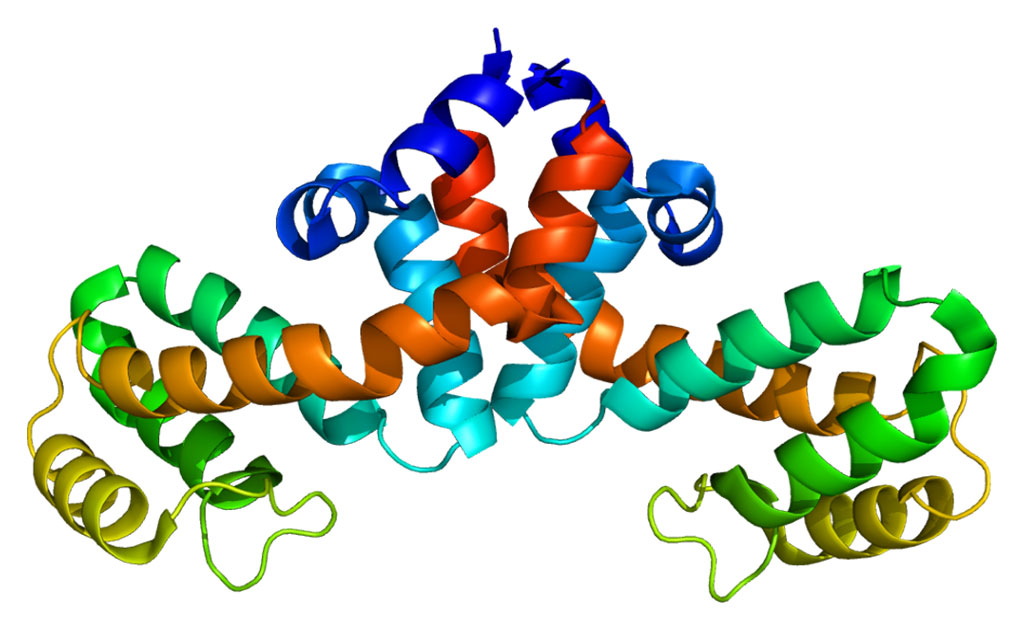

Called PRINT (particle replication in nonwetting templates), the technology enables the fabrication of custom-sized, monodispersed, and shape-specific particles of virtually any material and encapsulating nearly any active cargo. The latter includes delicate substances, biologic agents, and small molecules, which can be delivered through a full range of injectable, pulmonary, topical, and oral methods.

"This technique allows for development of a particle foundry, similar to continuous manufacturing techniques in the microelectronics industry, but for fabricating delicate particles for use in nanomedicines and other emerging technologies,” said Dr. W. Lowry Caudill, executive chairman of Liquidia Technologies (Research Triangle Park, NC, USA).

"Nanoparticle fabrication, until now, has focused on inorganic materials such as metals that involve harsh manufacturing methods and often are not useful for medical applications,” explained Joseph M. DeSimone, co-founder of Liquidia Technologies and professor of chemistry and chemical engineering at the University of North Carolina at Chapel Hill (USA). "This technology allows for the first time fabrication of particles for vaccines and therapies that are nontoxic for patients since the particles themselves are made from well-known bioabsorbable organic materials. Impressions are made with what we call liquid Teflon, and the resulting molds look something like ice cube trays with tiny cavities in them. After that, we mold the carrier and fragile functional materials into whatever particles we want.”

Related Links:

Liquidia Technologies