3D Printing Breakthrough Enables Large Scale Development of Tiny Microfluidic Devices

Posted on 17 Mar 2025

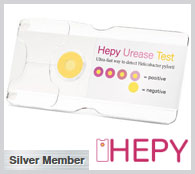

Microfluidic devices are diagnostic systems capable of analyzing small volumes of materials with precision and speed. These devices are used in a variety of applications, including cancer cell analysis, drug screenings, single-cell isolation, and point-of-care diagnostics. By controlling fluid flow and reaction conditions at the microliter or nanoliter scale, they facilitate advancements in biomedical research, enhance the accuracy and efficiency of diagnostic tests, and offer portable testing solutions across multiple fields. Traditionally, manufacturing microfluidic devices is expensive and labor-intensive, involving several steps and requiring high-end equipment and cleanroom environments. Now, a new innovation promises a quicker and more cost-effective method for producing these devices without the need for specialized facilities or expensive equipment.

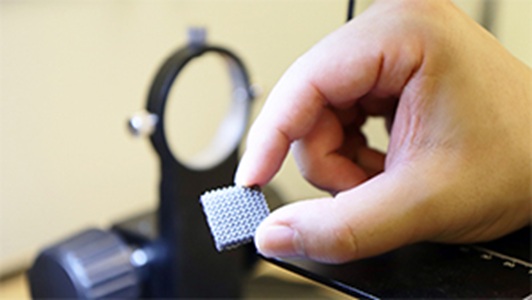

Researchers at Purdue University (West Lafayette, IN, USA) are their patent-pending technique to fabricate affordable, multilevel microfluidic devices with dimensions as small as 10 microns deep and 100 microns wide. To put this into perspective, one micron is one-millionth of a meter, and 10 microns is one-tenth of the width of a human hair. The team's method leverages 3D printing, which constructs objects layer by layer, providing a faster and simpler alternative to the traditional fabrication process. While fused filament fabrication (FFF), a widely used 3D printing technique, has proven effective, it struggles to create smooth, narrow channels smaller than 500 microns. The team is improving upon traditional fabrication methods and 3D printing by using vat photopolymerization (VPP) which enables the direct fabrication of highly transparent microfluidics with a much higher resolution, allowing for channels as narrow as 100 microns. A key aspect of their technique involves using liquid crystal display (LCD) technology, which employs ultraviolet light to solidify the photopolymer and facilitate the fabrication process.

One critical application of microfluidics is single-cell analysis, where channel widths need to match the size of individual cells. The researchers successfully printed a microfluidic channel capable of forming a single line of cancer cells as they flowed through it, showcasing the technology’s potential for precise cell analysis. In addition to validating this concept by creating a single line of cancer cells, the team also fabricated intricate microfluidic networks that replicate the structure of capillaries. Furthermore, they have extended their approach to 3D print microfluidic devices with channels on curved surfaces. The results of this research were presented at the ASME International Mechanical Engineering Congress and Exposition, underscoring the potential of this innovative method to revolutionize microfluidic device fabrication across various industries.

“Our next development steps are bridging 3D printed microfluidic devices with conventional 2D microfluidics, which can combine the advantages of both 3D printing and 2D nanofabrication,” said Huachao Mao, assistant professor of engineering technology in the Purdue Polytechnic Institute, who is leading the research team.